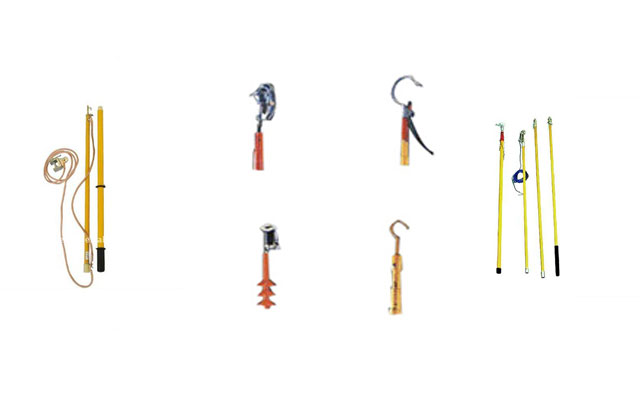

Discharging Rod

Manufacturer, Exporters, Dealers, and Suppliers of Discharging Rod in ahmedabad, gujarat, india

Features

- Construction :

Made of high-dielectric strength insulating materials such as fiberglass or epoxy resin.

Equipped with a metal hook or probe at the end for contacting live parts.

Connected to a flexible earthing cable that is clamped to a proper grounding point. - Insulation : Provides excellent dielectric strength to withstand high voltages (typically used in 11kV to 33kV systems or more).

- Design : Typically telescopic or sectional, allowing use from a safe distance.

Advantages

- Protects personnel from accidental shocks due to stored charges.

- Essential for safe maintenance of high-voltage systems.

- Portable, lightweight, and easy to use.

- Helps comply with electrical safety standards.

Applications

- Substations and HT panels

- Capacitor banks and transformers

- Transmission and distribution lines

- Vacuum and SF6 circuit breakers

Best Quality Discharging Rod Suppliers In Ahmedabad, Gujarat, India.

Discharging Rod, also known as an Earthing Rod or High Voltage Discharge Rod, is a safety tool used to manually discharge residual or trapped voltage from high-voltage equipment before maintenance or inspection. It ensures that the equipment is at zero potential, thereby protecting personnel from electric shock.

discharging rod is a specialized device engineered to safely dissipate static electricity from objects or surfaces, thereby mitigating the risks associated with static charge accumulation. Typically constructed from a conductive material, such as metal or a conductive polymer, the rod facilitates the transfer of electrical charge, allowing any built-up static electricity to be neutralized effectively. This process is crucial in various settings, particularly in industries where static electricity can lead to significant hazards, such as electronics manufacturing, pharmaceuticals, and the handling of flammable materials.

In electronics manufacturing, for instance, static discharge can damage sensitive components, leading to costly repairs and production delays. The use of an electrical discharging rod in such environments not only protects delicate equipment but also enhances overall operational efficiency. Similarly, in environments where flammable substances are present, static electricity can ignite vapors or dust, posing serious safety risks. By employing a discharging rod, workers can safely neutralize static charges before they become a threat, thereby ensuring a safer workplace.

Moreover, the design of these rods often includes features that enhance their usability and effectiveness. Many discharging rods are equipped with ergonomic handles for comfortable use, and some may even incorporate grounding mechanisms to ensure that any discharged electricity is safely directed away from personnel and sensitive equipment. The importance of managing static discharge cannot be overstated; it plays a vital role in maintaining safety standards and operational integrity across various industries. By effectively neutralizing static electricity, electrical discharging rods contribute significantly to the protection of both personnel and equipment, fostering a safer and more efficient working environment.